A-Star Photonics について

A-Star Photonics は、中国/福州に本社を置く、光学部品、結晶材、高精度光学機器等に注力するメーカーです。

当社はA-Star Photonicsの代理店です。

ラインナップ

Crystal

BBO Crystal

用途

- レーザークリスタル

- NOPAクリスタル他

仕様

| Flank Size(W*H) | 1×1~25×25 |

|---|---|

| Length(L) | 0.005~25 mm |

| Phase Matching Angle(θ,φ) | Angel or according to customer request |

| Match Type | type I or type II |

| Angle Tolerance | Δθ<±0.2°; Δφ<±0.2° |

| Size Tolerance | (W ±0.1 mm) x (H ±0.1 mm) x (L +0.2 mm/-0.1 mm) |

| Flatness | <λ/8 @ 633 nm |

| Smooth Finish | 20/10 |

| Parallelism | <30″ |

| Perpendicularity | <10′ |

| Wavefront Distortion | <λ/8 @ 633 nm |

| Clear Aperture | > 90% |

| Coating | P-coating or according to customer request |

LBO Crystals

用途

- 超高速 Ti:sapphireレーザー

- 光学パラメータ式発振器

- 光パラメトリック増幅器他

特性

| Crystal Structure | Orthorhombic, mm2 |

|---|---|

| Cell Parameters | a = 8.4473, b = 7.3788Å, c = 5.1395Å, Z = 2 |

| Melting point | 834°C |

| Optical homogeneity | d n ~ 10-6/cm |

| Mohs hardness | 6 |

| Density | 2.47 g/cm3 |

| Absorption coefficient | < 0.1%/cm (at 1064 nm and 532 nm) |

| Specific heat | 1.91J/cm3xK |

| Hygroscopic susceptibility | low |

| Thermal expansion coefficients | a, 4 x 10-6/K; c, 36 x 10-6/K |

| Thermal conductivity | ^ c, 1.2 W /m /K ; //c, 1.6 W /m /K |

LiNbO3 & MgO:LiNbO3

用途

- ポッケルセル

- Qスイッチ

- 位相変調器

- 弾性表面波(SAW)ウエハー

特性

| Crystal Structure | Trigonal, space group R3c |

|---|---|

| Cell Parameters | a=0.515,c=13.863,Z=6 |

| Melting Point | 1255 +/-5℃ |

| Curie Point | 1140 +/-5℃ |

| Mohs Hardness | 5 |

| Density | 4.64 g/cm3 |

| Absorption Coefficient | ~ 0.1%/cm @ 1064 nm |

| Solubility | insoluble in H2O |

| Relative Dielectric Constant | εT11/ε0: 85 εT33/ε0:29.5 |

| Thermal Expansion Coefficients at 25℃ |

||a, 2.0 x 10 -6/K @ 25℃ ||c, 2.2 x 10 -6/K @ 25℃ |

| Thermal Conductivity | 38 W /m /K @ 25℃ |

DKDP&KDP

特徴

- 優れた UV透過

- 高い光学損傷閾値

- 優れた複屈折及び非線形係数

用途

- 高出力レーザー 周波数変換物質

- 高速写真撮影用シャッター

- 電気工学変調機及びQスイッチ他、

KD*P Single A-STAR— Standard

| Designation | Operation | Input | Output |

|---|---|---|---|

| 53.7° | SHG (II) | 1064 nm | 532 nm |

| 59.5° | THG (II) | 1064 nm + 532 nm | 355 nm |

| 86° | FHG (I) angle tune | 532 nm | 266 nm |

| 90° | FHG (I) temp. tune | 532 nm | 266 nm |

| Wavefront distortion | less than l/8 @ 633 nm |

|---|---|

| Dimension tolerance | (W± 0.1 mm) x (H±0.1 mm) x (L + 0.2 mm/-0.1 mm) |

| Clear aperture | > 90% central area |

| Flatness | l/8 @ 633 nm |

| Scratch/Dig code | 10/5 to MIL-O-13830A |

| Parallelism | better than 20 arc seconds |

| P erpendicularity | 5 arc minutes |

| Angle tolerance | Dq <± 0.3°, Df <±0.3° |

| Quality Warranty Period | one year under proper use |

KTP

特徴

- 大きな 非線形光学係数

- 幅広い温度及びスペクトラル帯域幅

- 高電気工学係数及び低い誘電率

- 非吸湿性、優れた化学及び機械的特性

用途

- Nd-ドープレーザー(緑・赤色出力)の周波数倍増

- Ndレーザー及びレーザーダイオード(青色出力)の周波数混合

- 0.6 mm-4.5 mm 可変出力の為のパラメトリック源(OPG, OPA and OPO)

- E-O 変調機、光学スイッチ、方向性結合器他、

| ATTRIBUTE | COMMERCIAL | HIGH PRECISION |

|---|---|---|

| Wavefront Distortion | λ/8 | λ/8 |

| Orientation | ±0.5° | ±0.2° |

| Dimension Tolerance | ±0.1 mm | ±0.01 mm |

| End-faces Configuration | Flat | |

| Surface Quality | 20-10 scratch and dig | 0-5 scratch and dig |

| Flatness | λ/8 | λ/10 |

| Parallelism | 20″ | 10″ |

| Intrinsic Loss | 50ppmcm-1@ 1064 nm | |

KTA Crystal

特徴

- 幅広い温度及びスペクトラル帯域幅

- 低誘電率、低損失係数、イオン伝導率

- 高い損傷閾値

用途

- 周波数倍増 (SHG @1083nm-3789nm)

- 和周波数及び差周波数(SFG)/(DFG)他

| KTA Crystal Specification | |

|---|---|

| Dimension Tolerance | ±0.1 mm |

| Flatness | <λ/8 @633 nm |

| Surface Quality | 10/5 Scratch/Dig |

| Parallelism | better than 30 arc sec. |

| Perpendicularity | better than 30 arc min |

| Angle Tolerance | △q < 0.5°,△f < 0.5° |

| AR Coating | AR coatings |

| Clear Aperture | >90% central area |

| Transmitting Wave front Distortion | less than l/8 @ 633 nm |

Nd:YAG

用途

- レーザー媒体(個体レーザー)

仕様

| Nd Dopant Concentration | 0.5-1.2 atm%tolerance within 10% of concentration |

|---|---|

| Diameter | 3 ~ 14 mm |

| Length(L) | 0.5~160 mm |

| Orientation | <111> crystalline direction (+/-0.5℃) |

| Flatness | <λ/8 @ 633 nm |

| Smooth Finish | 20/10 |

| Parallelism | <30″ |

| Perpendicularity | <10′ |

| Wavefront Distortion | < λ/8 @ 633 nm |

| Clear Aperture | > 90% |

| Coating | According to customer request |

Optical Components

平凸レンズ(plano-convex lenses)

仕様

| Material | BK7, Fused Silica, SF10, CaF2, Sapphire .etc. |

|---|---|

| Paraxial Focal Length Tolerance | ±2% |

| Dimension Tolerance | ±0.2(General). ±0.05(High Precision) |

| Centration | <3 arc min |

| IRR | λ/4@633 nm(General),λ/10@633 nm(High Precision) |

| Clear Aperture | >80%(Small Size), >95%(Large Size) |

| Surface Figure | <1.5λ@633 nm(General),<λ/4@633 nm(High Precision) |

| Surface Quality | 60/40(General),10/5(High Precision) |

| Bevel | <0.25 mm |

| Coating | Uncoated, AR,PR, HR, etc. |

平凹レンズ(plano-concave lenses)

用途

- 焦点距離増大(既存システム)

仕様

| Material | BK7, Fused Silica, SF10, CaF2, Sapphire .etc. |

|---|---|

| Paraxial Focal Length Tolerance | ±2% |

| Dimension Tolerance | ±0.2(General). ±0.05(High Precision) |

| Centration | <3 arc min |

| IRR | λ/4@633 nm(General),λ/10@633 nm(High Precision) |

| Clear Aperture | >80%(Small Size), >95%(Large Size) |

| Surface Figure | <1.5λ@633 nm(General),<λ/4@633 nm(High Precision) |

| Surface Quality | 60/40(General),10/5(High Precision) |

| Bevel | <0.25 mm |

| Coating | Uncoated, AR,PR, HR, etc. |

Achromatic Double Lens

用途

- 有色及び球面収差効果の制限

仕様

| Material | BK7 glass and ZF2 or ZF4 |

|---|---|

| EFL | +/- 2% |

| Diameter | +0, -0.18 |

| Center thickness tolerance | +/- 0.20 |

| Surface quality | 40/20 scratch/dig |

| Centeration | 2 arc minimum |

Cylindrical Lens

用途

- バーコードスキャニング

- レーザー計測システム

- ホログラフィ

| Material | BK7(H-K9L), fused silica(JGS1),SF10(H-ZF13) |

|---|---|

| Surface Figure | λ /2@633 nm on plano side |

| Surface Quality | 60/40 Scratch/Dig |

| Dimension Tolerance | + 0.0 mm, – 0.1 mm |

| Thickness Tolerance | ± 0.2mm |

| Chamfer | 0.25 mm at 45° typical |

| Concentricity | 3 minutes |

| Focal Length Tolerance | ± 1% typical |

| Antireflection Coating | Wavelength user specified |

| R 0.25% for V-type AR coating | |

| R 0.5% for BBAR coating, per surface. | |

| Clear Aperture | Exceeds central 85% of dimension |

偏光光学(Polarization Optics)

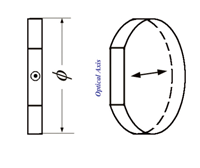

ローオーダー波長板(Low Order Waveplate)

シングルプレートローオーダー波長板

仕様

| Material | Quartz |

|---|---|

| Dimension Tolerance | +0.0/-0.1 mm |

| Surface Quality | 20/10 |

| Flatness | λ/8@633 nm |

| Parallelism | <1 arc Second |

| Retardation Tolerance | λ/300 |

| Clear Aperture | >90% |

| AR Coated | R <0.2%@Wavelength |

| Standard WaveLength | 266 nm,355 nm,532 nm,63.28 nm,780 nm,808 nm, 850 nm,980 nm,1064 nm,1310 nm,1480 nm,1550 nm |

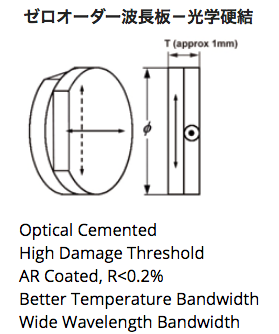

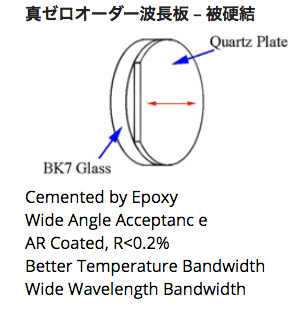

ゼロオーダー波長板(Zero Order Waveplate)

仕様

| Attribute | Specification |

|---|---|

| Material | Quartz |

| Dimension Tolerance | +0.0/-0.1 mm |

| Surface Quality | 20/10 Scratch/Dig |

| Flatness | λ/8@633 nm |

| Parallelism | <1 arc Second |

| Retardation Tolerance | λ/500 |

| Clear Aperture | >90% |

| AR Coated | R <0.2%@Wavelength |

| Standard Wavelength | 266 nm,355 nm,532 nm,63.28 nm,780 nm,808 nm, 850 nm,980 nm,1064 nm,1310 nm,1480 nm,1550 nm |

デュアルウェイブレングス波長板(Dual wavelength Waveplate)

Dual Wavelength Waveplate

仕様

| Material | Quartz |

|---|---|

| Dimension Tolerance | +0.0/-0.1 mm |

| Surface Quality | 20/10 |

| Flatness | λ/8@633 nm |

| Parallelism | <1 arc Second |

| Retardation Tolerance | λ/300 |

| Clear Aperture | >90% |

| AR Coated | R <0.2%@Wavelength |

| Standard WaveLength | 800 nm&400 nm,1064 nm&532 nm |

Lens Assembly

レンズアッセンブリ(Lens Assembly)

カスタム化にも対応し、顧客ニーズに応じ、設計及び製造が可能です。

| lens assemblies Types | Optical Assemblies, lens assembly |

|---|---|

| Lens Assembly |  |

| Precision Optics Assembly (Supply mounting for various Crystals, Beamsppliers, ,Polarizers, Waveplates etc.) |

|

| Other Lenses Assembly (OEM ) |

|